| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Pinhe |

| Model Number : | G2034S |

| Certification : | ISO CE |

| Price : | 500000~600000USD/SET |

| Payment Terms : | T/T,L/C |

| Supply Ability : | 20 sets/month |

| Delivery Time : | 2 months |

Multi Wire Saw Marble Cutting Machine Super Thin Wire Saw Machine for Block Squaring Stone Cutting

Product Introduction

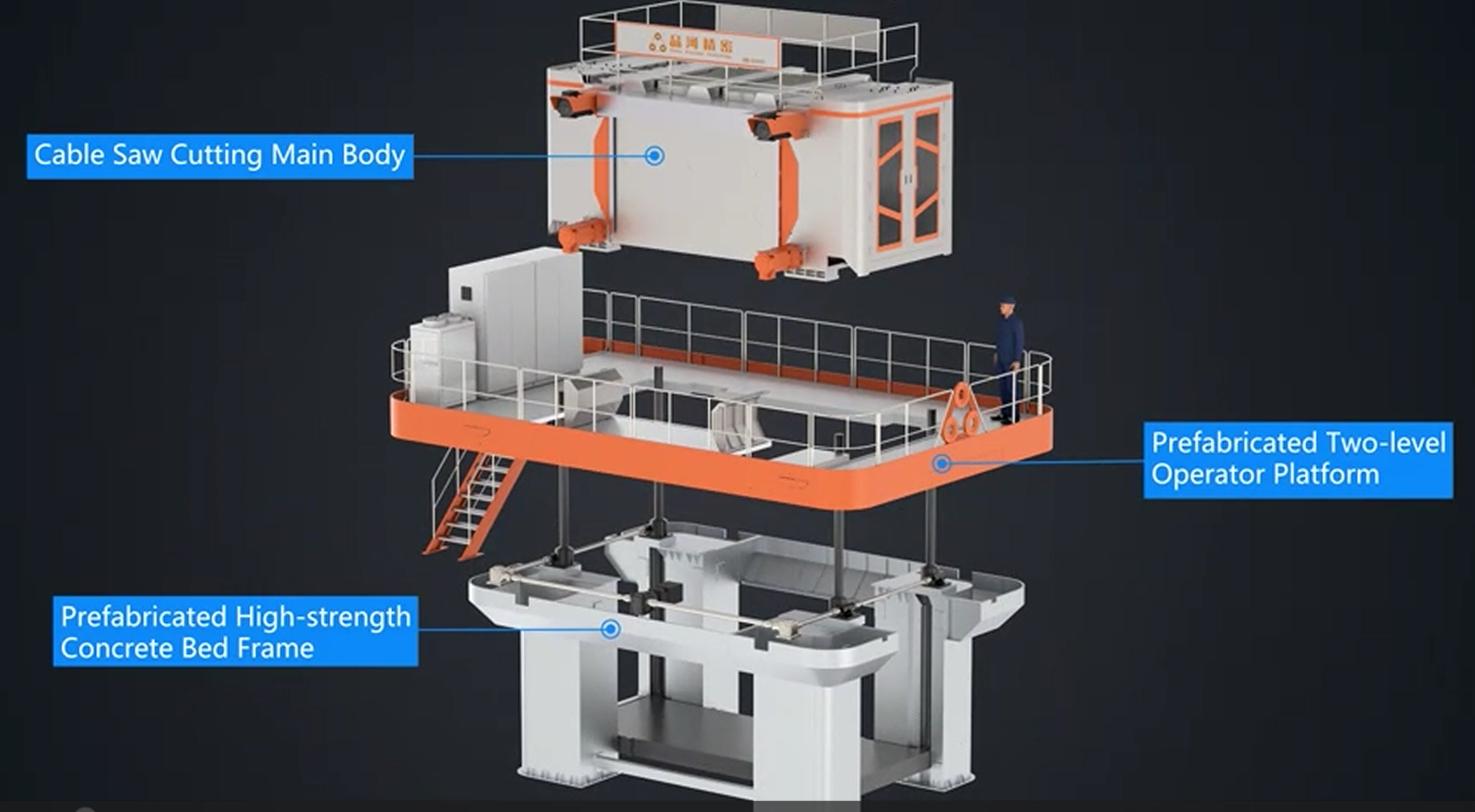

PINHE Advanced Gulf-Style Modular Lifting Wire Saw

Engineered for next-level efficiency, the latest generation Gulf-style lifting wire saw from PINHE features a fully modular design tailored for modern stone processing facilities. Pre-fitted with precision-cast column bases and a two-level operator platform, it eliminates the need for traditional concrete foundations or additional structural work—dramatically reducing installation time and associated costs.

This innovative setup combines form and function: a sleek, contemporary profile matched with high-performance architecture. The system supports bi-directional material feeding, significantly boosting cutting efficiency and throughput. Whether upgrading an existing line or building from scratch, this machine brings powerful flexibility to every operation.

Effortless Upgrade from Traditional Gang Saws

Upgrading from traditional gang saws to the PINHE Gulf-style lifting wire saw is a simple and efficient process. The existing machine can be removed, and the new wire saw can be installed directly onto the original base structure—no need for costly or time-consuming foundation changes. This seamless transition allows you to maintain your current material handling system, minimize downtime, and significantly reduce renovation costs. With minimal disruption to your operations, you can quickly achieve a high-performance upgrade, enhancing your factory’s productivity with ease.

Upgraded Features of the Next-Generation Gulf-Style Lifting System

The latest version of the Gulf-style lifting system incorporates several advanced upgrades focused on enhancing durability and operational reliability. Key improvements include reinforced waterproofing for the wire take-up and release chambers, with sealed enclosures at both the wire entry and exit points to effectively prevent water ingress. The wire-guiding system has been upgraded to an oil-lubricated sliding track, ensuring smoother movement and minimizing wear over time. Additionally, strategically placed water-resistant baffles near the motor protect sensitive electrical components from moisture and water mist, significantly boosting the system’s longevity and performance in wet or high-humidity environments.

Improved Accessibility and Advanced Cooling System

To enhance ease of operation, the latest model includes a newly integrated observation ladder—making it significantly easier for operators to align and adjust the wire’s entry and exit points. This addition streamlines setup and routine maintenance, improving overall workflow efficiency.

The cooling system for the spindle and motor has also received a major upgrade. Featuring a re-engineered pipeline layout, each component now runs on an independent water circuit, all connected through a centralized mainline. This intelligent design ensures stable and uniform cooling, effectively managing heat dissipation and minimizing the risk of thermal stress. As a result, the system delivers improved long-term reliability and extends the service life of key components.

Next-Generation Control System with AI-Driven Cloud Intelligence

The newly enhanced control system is fully integrated with the PINHE AI-Powered Digital Monitoring Cloud Platform, enabling real-time, remote oversight of machine performance and cutting operations. Equipped with high-definition smart cameras and millimeter-wave radar sensors, the system provides precise, automated tracking across every stage of the cutting process.

By intelligently adapting process parameters to live conditions, the platform ensures full closed-loop control—optimizing both cutting techniques and final output. This high level of automation enhances cutting precision, improves operational efficiency, reduces consumable usage, and minimizes reliance on operator skill—delivering consistent, high-quality results with maximum productivity.

Product Parameters

| Block Entry into Machine | From side (as picture shown above) |

| Trolley Movement | Trolley (block) going up |

| Dimension | 6M(L) * 4M(W) * 6.5M(H) |

| Motors | Siemens Servo Motor Control System Main Motor 60kw |

| Total Power | 300kw |

| Processing Size | L3400mm * W2000m * H2200mm |

| Cutting Wire Speed | 0-35m/min |

| Cutting Down Feed | 0-25cm/h |

| Roller Material | Aviation Aluminum Roller ф350mm |

| Wire Storage | 30-50km |

| G.W | 45 Tons |

| Bearing Housing | German NSK Bearing with High Speed Housing |

| Wire Diameter | 0.38mm - 0.8mm |

| Main Body | Cast Iron |

| PLC | AI Automatic Control System of Siemens |

Why Choose Pinhe Precision?

1. Pioneers in Diamond Wire Saw Technology

Pinhe Precision is the original innovator in diamond wire saws for

stone processing, backed by over six years of intensive R&D.

Now in our ninth generation, our equipment is protected by more

than 50 patents—including over 20 invention patents and two

software copyrights—giving us the legal leverage to defend our

technology. While imitators may replicate the appearance, they

can’t match our ability to innovate or solve real-world problems.

Pinhe's experienced R&D team ensures ongoing advancement and

product excellence.

2. Customer-First Service Commitment

We treat every machine as if it were our own. Understanding the

critical nature of after-sales support, especially for new

technology users, Pinhe has built a rapid-response service

network—featuring over 40 technicians in Shuitou and 10+ in Yunfu.

Our team is available 24/7, offering on-site service within one

hour in most cases. We guarantee machine downtime doesn’t exceed

eight hours under normal conditions, helping you maintain steady

productivity.

3. Field-Proven Reliability

Pinhe machines are not just engineered—they’re field-tested. Our

second-generation down-pressing model has run reliably since 2019,

while the third-generation lifting system has operated smoothly for

more than 3.5 years. These extensive use cases have revealed and

resolved real-world challenges, resulting in refined, dependable

equipment that evolves through experience—not theory.

4. High-Speed, Precision Engineering

Efficiency starts with speed. Since our fourth generation, we’ve

integrated high-speed spindles, one-piece cast bodies,

aviation-grade aluminum guide wheels, and advanced bearing

housings—achieving speeds of up to 2,000 RPM. This premium

engineering allows for faster, more accurate cuts with excellent

structural integrity. Today, more than 70% of premium marble in

Shuitou is processed using Pinhe machines—a testament to our

precision and trustworthiness.

5. Cost-Efficient Operation

Pinhe’s robust design and low wire breakage rates lead to lower

consumable costs and extended uptime. Customers save 20–30% on

operational expenses—including diamond wire, rollers, and

labor—compared to conventional machines. For stones like Baiyulan

and Altman, average cutting costs range from 9–12 RMB/m²; for

tougher materials like Venice Brown, costs stay around 15 RMB/m².

The result? Higher efficiency and better margins.

6. Market Leadership and Global Expansion

Pinhe holds a leading position in China’s major stone-processing

regions—with over 80 units installed in Shuitou and 29 in Yunfu,

plus 20+ more in production. Internationally, 25 machines are

already in use, with another 20+ en route. Our expanding global

presence ensures strong, dependable service and continued growth

across borders.

7. Values You Can Rely On

At Pinhe, integrity, innovation, quality, and customer commitment

are the pillars of our business. We don’t just sell machines—we build

long-term partnerships. Our mission is to help your business thrive

through reliable technology, responsive support, and shared

success.

|